Soil Nails

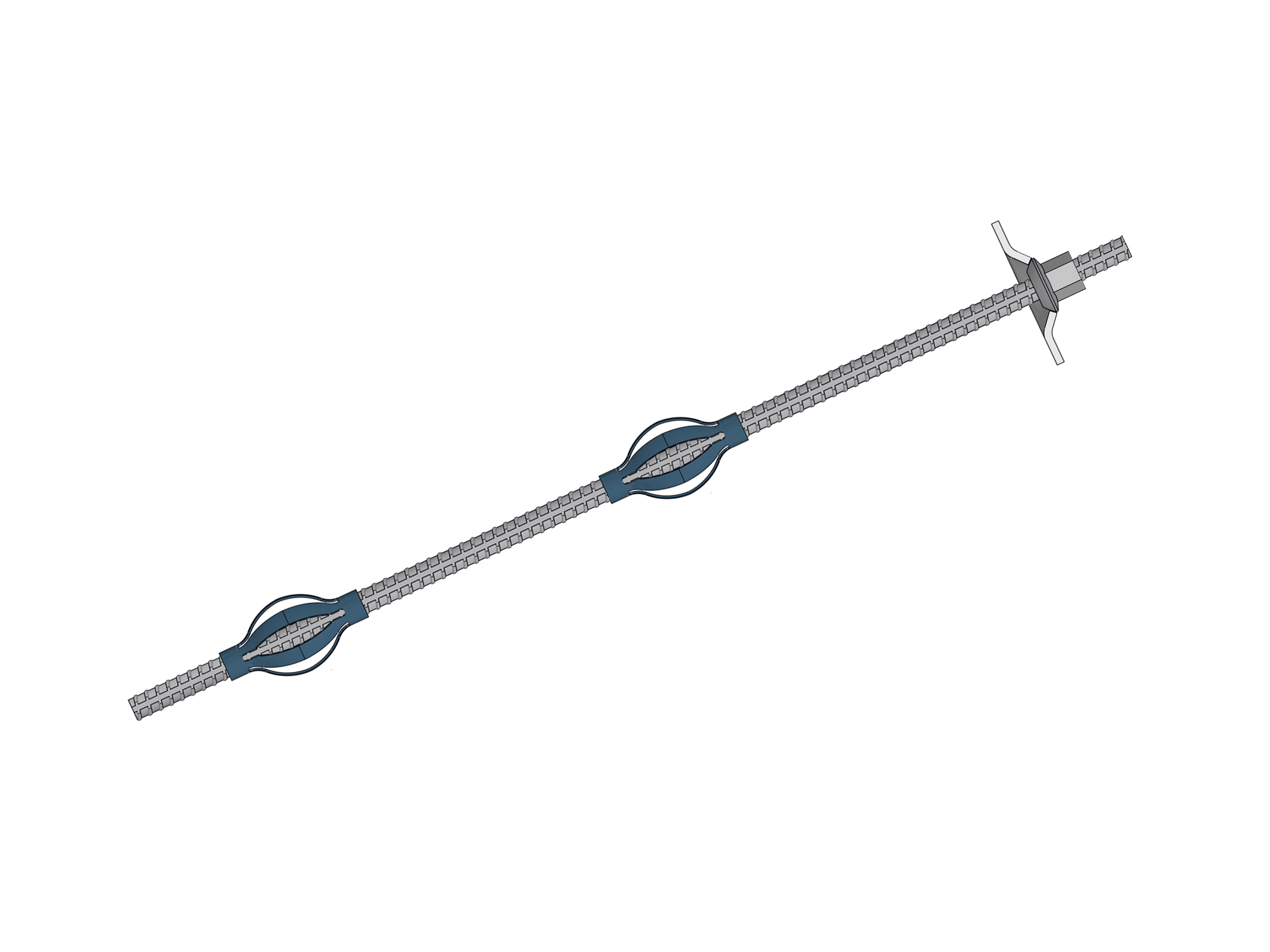

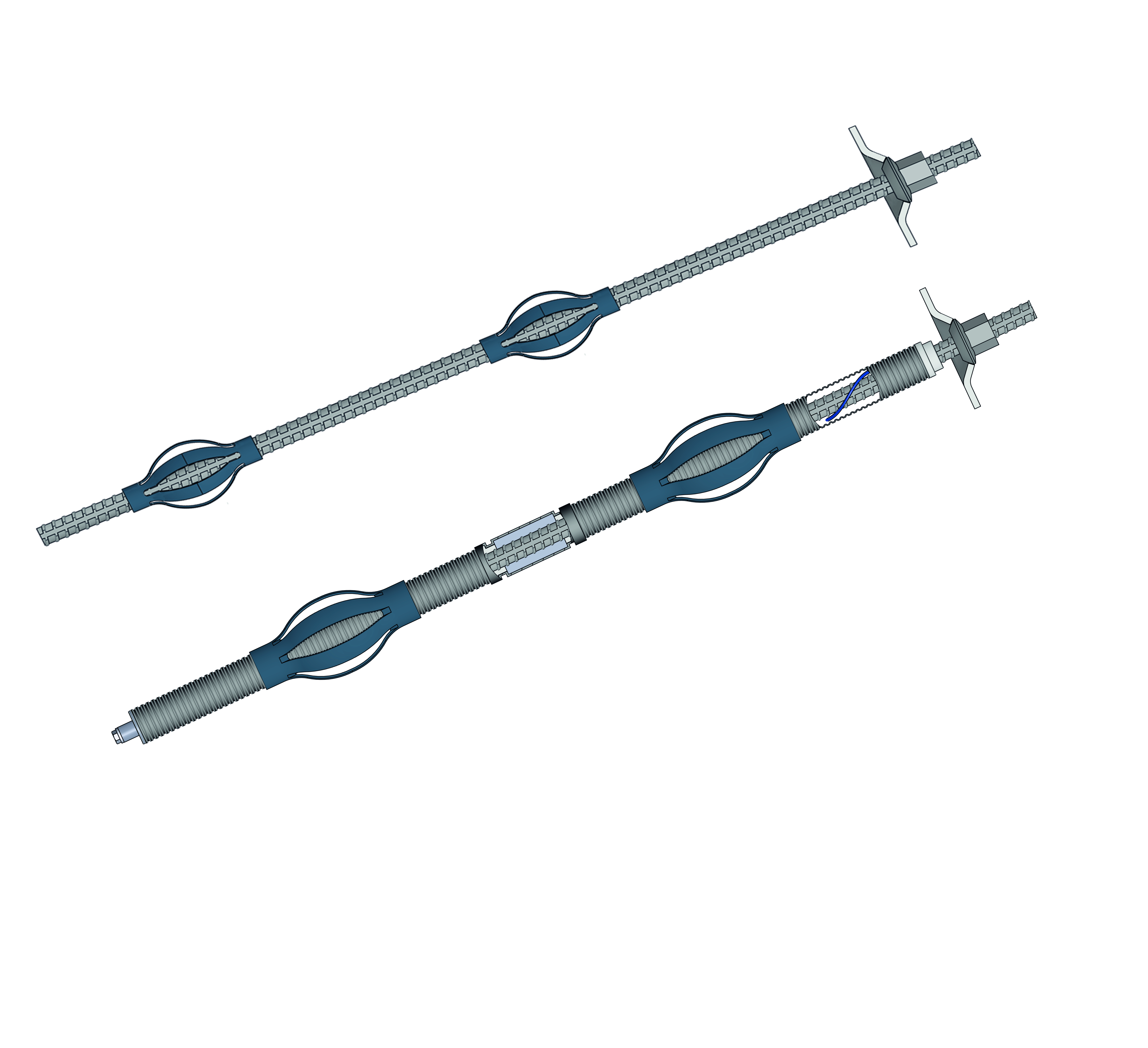

Our soil nails, also called rock bolts, rock nails or SN-anchors, are threaded steel bars tendons.

They are available in the following grades:

BSt 500 / 550 ∅ 16 - 50 & 75 mm

S 555 / 700 ∅ 57,5 & 63,5 mm

S 670 / 800 ∅ 18 - 75 mm

Soil nails consisting of self-drilling hollow core steel bars are featured separately.

Threaded soil nails offer the following advantages:

- Steel bars can be cut at any time and at any point along the bar. The remaining lengths remain screwable.

- Splicing of bars using couplers is simple and uncomplicated.

- The thread remains screwable even when dirty or damaged.

- Thread provides maximum shear bond between steel bar and cement grout.

Soil nails made from solid rods are available in the following construction variants:

Temporary Soil Nails

Galvanized Soil Nails